English

Capacidades

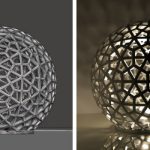

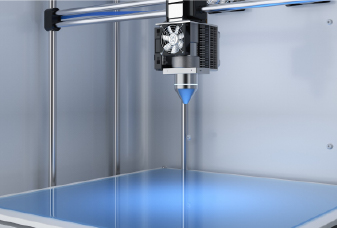

Creación rápida de prototipos y fabricación bajo demanda.

Industrias

Únase a miles de líderes de la industria que impulsan la innovación de productos con Chiggo.

Dispositivos médicos

Aeroespacial

Productos de consumo

Equipos industriales

Ofrecer innovaciones de forma rápida y segura a la atención sanitaria

Impulsar proyectos desde el plano hasta el despegue con eficiencia

Dando forma a productos que definen la vida moderna, desde la idea hasta el uso

Impulsando el progreso con maquinaria avanzada para una productividad superior

Soluciones

Una solución integral desde las materias primas hasta la producción y la mejora del producto.

Sobre nosotros

Descubra quiénes somos y cómo garantizamos la calidad y la entrega oportuna.

Acerca de Chiggo

Acerca de la entrega

Seguro de calidad

Nuestra fábrica

Nuestra visión, misión, historial de desarrollo y equipo dedicado.

Tiempos de respuesta rápidos y eficientes, optimizando cada paso desde la realización del pedido hasta la entrega.

Entregamos prototipos rápidos de calidad y piezas de producción bajo demanda que cumplen y superan las expectativas.

Descubra la precisión y la innovación detrás de Chiggo con un recorrido por nuestra fábrica, disponible en línea o in situ.

Recurso

Todo lo que necesitas saber sobre la fabricación digital.

-

Blog

-

Video

Su fábrica de fuentes confiablesDesde 2011

-NC加工-448X301.jpg?width=448&height=301)