English

行业

加入成千上万的行业领导者的行列,与 Chiggo 一起推动产品创新。

解决方案

从原材料到生产和产品增强的一站式解决方案。

资源

您需要了解的有关数字化制造的一切。

几乎我们日常使用的每一种产品,从智能手机到汽车,其起源都可以追溯到制造过程。这些流程不仅决定产品的质量和生产效率,还直接影响企业的成本控制和市场竞争力。在本文中,我们将定义制造工艺,深入研究它们的类别和各种方法。现在让我们开始探索它们的广泛含义!

在讨论制造过程需要什么之前,让我们花点时间看一下制造的大局。制造是通过使用工具、机械和劳动力将原材料或部件转化为成品的过程。

制造业的历史起源于史前时代,当时人类首次使用简单的工具来切割、压碎和塑造材料。随着时间的推移,随着文明的进步,制造技术的复杂性和精密度也在不断提高。工业革命标志着一个重要的转折点,引入了蒸汽动力、机械化和大规模生产方法,彻底改变了商品的制造方式。如今,制造流程已经高度自动化,并与机器人技术、计算机数控 (CNC) 加工和 3D 等先进技术相集成印刷。

制造过程是指在更广泛的制造活动中生产特定产品的具体方法和操作顺序。它包括设计、材料选择、加工、质量控制和最终组装等多个阶段。每个阶段对于塑造成品的整体性能和生命周期都至关重要。

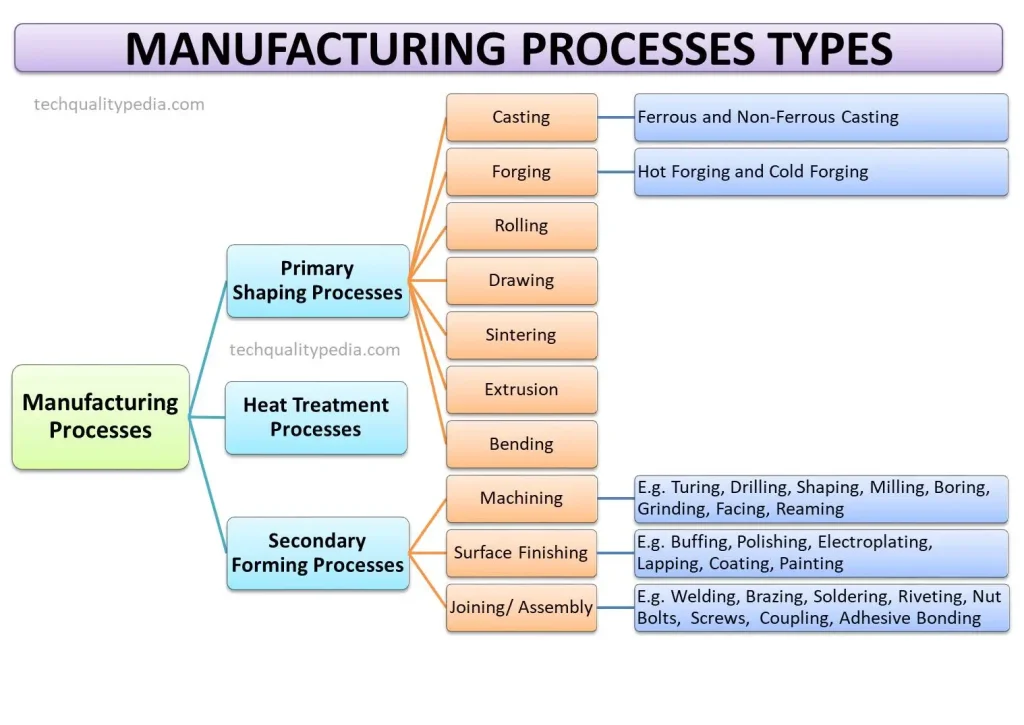

根据生产方式和生产成品的类型,制造工艺可分为多种类型,每种类型都有其自身的特点和应用。一般来说,制造工艺有五类。

车间制造是一种高度灵活的生产模式,专为小批量、多品种的要求而设计。它专注于独特的定制产品,这些产品通常需要专门的工具和设置时间。在客户订单的驱动下,加工车间可以迅速适应多样化的生产需求。然而,这种灵活性对预测工作流程模式提出了挑战,因为生产涉及多个、复杂的非线性操作。尽管存在这些复杂性,加工车间制造仍然是小批量或原型生产重型设备、机械或专用产品的行业的理想选择。

离散制造涉及生产不同的、可计数的产品,这些产品通常由各种单独的零件或组件组装而成。这种类型的制造侧重于将这些单独的零件组装成成品。每件产品,例如汽车、计算机或电器,都是独一无二的,并且可以在整个生产过程中进行跟踪。离散制造涉及不同的操作,并且通常适应高度的定制。它通常用于汽车、电子和家具等行业。

重复制造的特点是长期重复生产相同或非常相似的产品。这种方法强调快速、大批量、相同地生产标准化产品。专用生产线和自动化装配机简化了流程,减少了对体力劳动的需求。质量控制对于确保一致性和最大程度地减少缺陷至关重要,因为材料不断流过一系列自动化步骤。这种方法对于生产汽车零部件、电路板和处理器以及大规模生产统一食品和饮料(如瓶装饮料和罐头食品)非常有效。

批处理制造是一种产品批量或批量生产而不是连续生产的生产方法。与离散制造和作业车间制造类似,批量流程制造根据客户订单或市场需求调整其生产计划。每个批次在开始下一个批次之前都会经历整个生产过程,从而允许批次之间的高度定制和灵活性。例如,在制药行业中,不同批次的药物是按照特定的配方和剂量生产的。每一批完成后,设备都会被清洁并为下一批做好准备,下一批可能是不同的药物或前一批的变体。

与重复制造一样,这种流程制造也提高了生产效率和标准化。在连续制造中,原材料不断流入生产系统,成品从另一端排出。这种不间断的生产通常用于液体、气体或其他可流动物质,例如化学品、石油产品以及食品和饮料。相反,重复制造适合生产高度标准化的产品,其中生产周期或批次之间可能存在暂停。

在每个类别中,都有各种方法和技术用于实现所需的结果。在下面的文章中,我们将讨论 7 种主要类型的制造方法及其子类型。

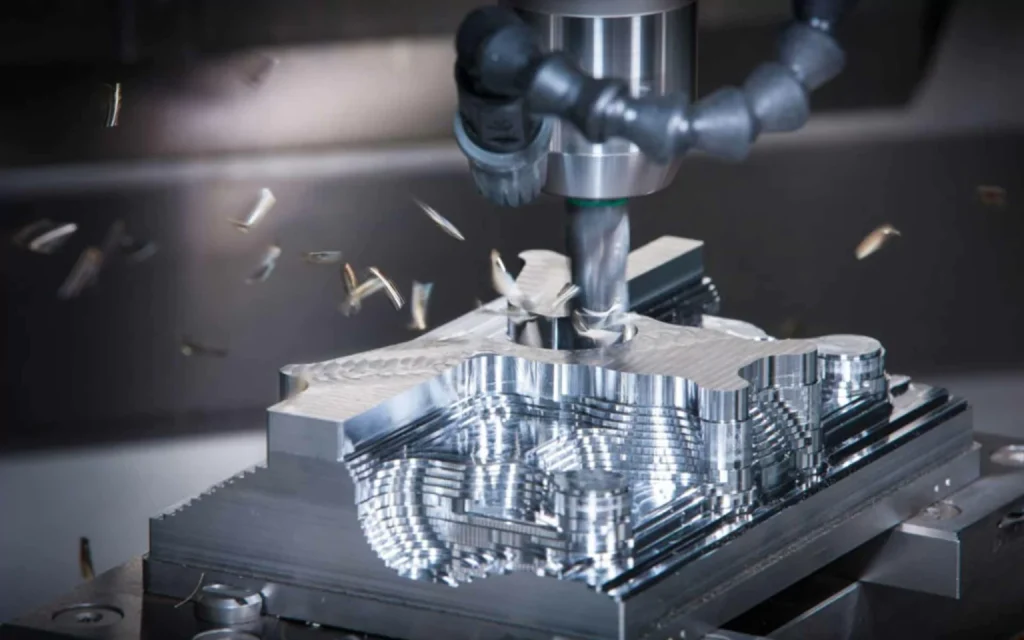

减材制造是一种多功能工艺,从固体块中去除材料以形成所需的形状。它适用于多种材料,包括金属、塑料、陶瓷和复合材料。现代减材制造工艺通过 CNC 技术实现自动化,确保高速、精确地加工复杂的细节和光滑的表面。车间制造和离散制造企业广泛使用减材工艺来生产定制零件和组件。

以下是常见的减材制造工艺:

连接是将两块或多块材料永久或半永久连接以创建组件的过程。该技术广泛用于制造通常无法直接生产的复杂产品。通过生产多个更简单的部件然后将它们连接起来,可以降低复杂零件的生产成本。此外,连接过程允许更换有故障的部件,而无需丢弃整个产品。加入过程的一些示例是:

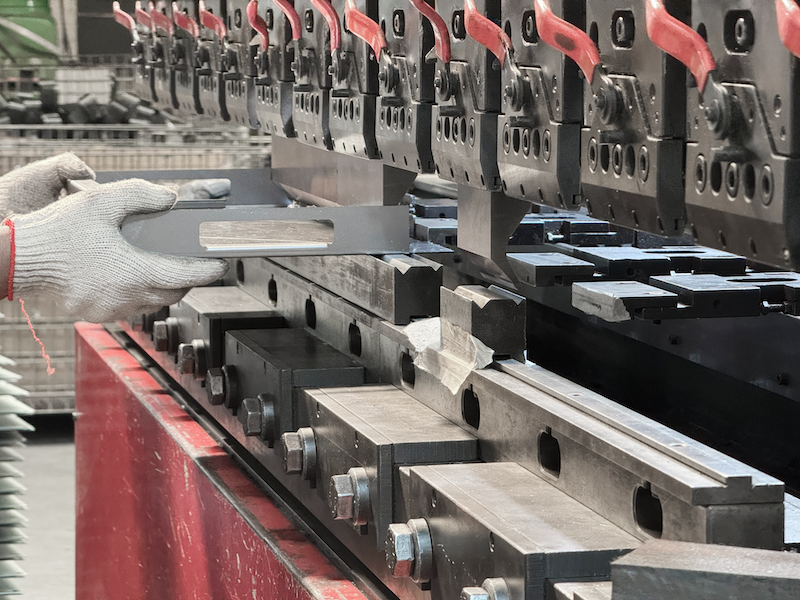

成型是一种制造过程,其中使用机械力改变材料(通常是金属)的形状,而无需添加或去除材料。该工艺基于材料的塑性变形,从而最大限度地减少材料浪费。成型过程中不同类型的制造工艺有:

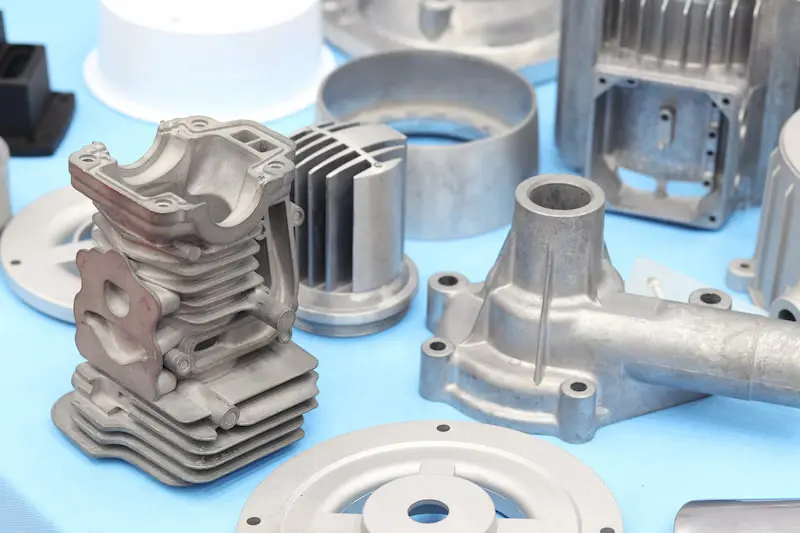

铸造涉及将液态金属倒入模具型腔中以制造具有特定形状的固体物体。一旦金属冷却并凝固,模具就会被移除,露出铸件。铸造涉及多种工艺,其分类包括以下几种:

其他铸造方法还有真空压铸、低压铸造、消失模铸造等,也以其独特的优势应用于各个行业,以满足特定的生产要求。

成型与铸造工艺类似,但成型更常见于塑料,而铸造主要涉及金属。在成型过程中,将熔融材料倒入模具中固化成所需的形状。尽管制造模具成本高昂且耗时,但该工艺非常适合批量生产具有精确尺寸和良好表面光洁度的零件。模具的可重复使用性也降低了生产成本。常见的成型方法有:

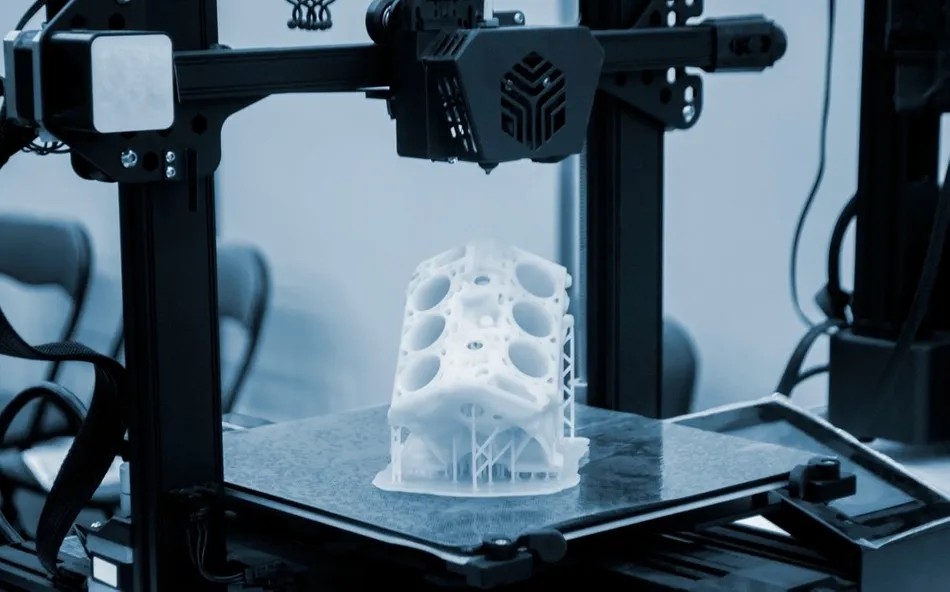

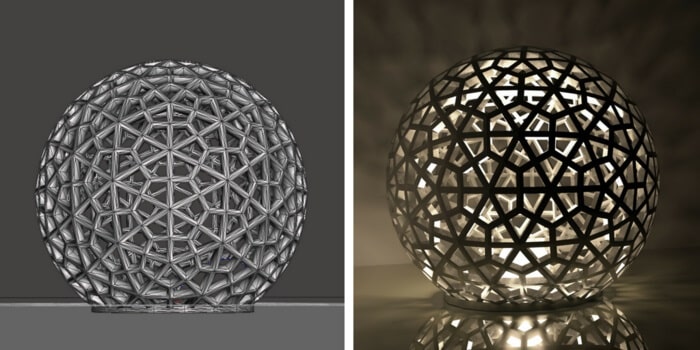

增材制造 (AM),通常称为 3D 打印,是一种基于数字模型,通过逐层添加材料来构建物体的过程。增材制造适用于可热成型的材料,包括金属和某些塑料,可实现高度定制、复杂的几何形状并减少材料浪费。常见的增材制造工艺类型如下:

表面处理工艺涉及应用于材料表面以增强其性能的各种技术,例如外观、耐腐蚀性、耐磨性和附着力。这些处理可以是机械的、化学的或电化学的。常见的表面处理类型包括喷砂、抛光、粉末涂层、电镀和阳极氧化。

根据客户需求和生产流程,制造和供应链管理中常用的制造策略有以下三种:

在按库存生产 (MTS) 方法中,制造商根据过去的销售数据、市场趋势和预测来预测未来的需求来生产商品。在收到任何特定客户订单之前,产品将被制造、组装并储存在仓库中。

这种方法可以快速履行客户订单,因为产品已经可用并准备发货。它通过提供即时可用性来最大限度地缩短交货时间并提高客户满意度。然而,如果需求预测不准确,它也会带来库存过剩的风险。

按订单生产 (MTO) 策略仅在客户下订单后才启动生产流程。制造商维持灵活的生产系统,能够根据不同的订单进行调整,通常生产周期较短。

虽然 MTO 降低了库存成本和过时的风险,但由于每个订单的生产都从头开始,因此通常会导致交货时间延长。此方法非常适合需求量低或定制程度高的产品。

按组装制造 (MTA) 也称为按订单组装 (ATO),是一种结合了 MTS 和 MTO 元素的混合方法。在这种模式中,制造商预先生产和库存组件或子组件,这些组件或子组件可以在收到客户订单后快速组装成最终产品。

与完整的 MTO 相比,该策略允许在一定程度上进行定制,同时保持更短的交货时间。 MTA 减少了生产过程中大量定制的需求,使其更加高效且更具成本效益。它还确保只生产必要的组件,最大限度地减少浪费和库存积压。 MTA 特别适合具有标准和可定制功能的产品。

关于制造工艺的类型,显然存在针对特定行业、产品和生产目标定制的多种方法。关于制造方法的讨论强调了可以帮助您实现产品效率、成本效益和质量的关键方面。在 Chiggo,我们为自己在 数控加工 和 钣金加工。此外,我们还提供 3D 打印和注塑服务,根据您的需求提供全面的解决方案。如果您有任何疑问,联系我们!

从微型电子产品到重型工业系统,几乎每件硬件都依赖机械紧固件才能有效运行。本文深入探讨了紧固件及其广泛的应用。准备好仔细看看了吗?加入我们,一起发现: 什么是紧固件? 不同类型的紧固件及其用途 用于制造紧固件的材料 如何为您的项目选择合适的紧固件 什么是紧固件? 紧固件是一种用于将两个或多个物体机械连接或固定在一起的硬件设备。它涵盖了广泛的工具类别——螺钉、螺母、螺栓、垫圈、铆钉、锚栓和钉子等各种形式。 大多数紧固件可以轻松拆卸和重新组装,而不会损坏螺钉和螺栓等部件。它们形成非永久性关节,但这并不意味着该关节很弱;事实上,如果安装正确,它们可以承受很大程度的压力。 此外,还有焊接接头和铆钉等紧固件,它们可以形成不易拆卸的永久结合。根据应用的不同,紧固件有各种形状、尺寸和材料,每种都有其独特的功能和用途。我们将在下面的段落中研究这些以及更多内容。 不同类型的紧固件及其用途 如上所述,紧固件有多种形式。每种类型都根据其设计和功能满足独特的应用。以下是紧固件主要类型、子类型和具体用途的详细分类。 类型 1:螺丝 螺钉是高度通用的紧固件,具有头部和螺纹杆,可提供强大的抓地力和抗拉力。它们有各种头部形状(例如扁平、圆形或六角形),可以适应不同的工具和审美需求。 与螺栓不同,许多螺钉(例如自攻螺钉)可以在材料中创建自己的螺纹,而无需预先钻孔。使用螺丝刀或电钻等简单工具即可快速安装,并且不需要螺母进行紧固。螺钉与多种材料兼容,包括木材、塑料和薄金属。一些最常见的包括: 木螺丝 顾名思义,木螺钉通常是部分螺纹的,专门设计用于连接木块。它们具有锋利的尖端和粗螺纹,使它们能够轻松穿透木材并提供牢固的抓握。 机械螺丝 与木螺钉相比,这些螺钉具有更细的螺纹,这使得它们更适合金属和刚性复合材料等硬质材料。它们具有一致的柄直径,尖端没有锥形。通常,机器螺钉插入预先钻好的螺纹孔中或与螺母配对以进行安全组装。 金属板螺丝 金属板螺钉是自攻螺钉专为薄金属板(如金属板)和其他薄材料而设计。它们具有全螺纹柄和锋利的螺纹尖端,可以轻松地将螺纹切削到薄金属中。 自钻螺钉 自钻螺钉采用金属板螺钉的全螺纹设计,但配有钻头形状的尖端。这一独特的功能使它们能够直接钻入钢或铝等硬质基材,而无需预钻孔。它们对于固定较厚的金属材料特别有效,可提高效率并易于安装。 甲板螺丝 与主要用于室内或受保护的木材连接的木螺钉不同,甲板螺钉是专门为室外应用而设计的木螺钉。它们通常由不锈钢、镀锌钢或具有特殊防腐涂层的材料制成。甲板螺钉通常具有全螺纹柄,有些设计采用双螺纹或特殊螺纹,以适应温度和湿度波动引起的膨胀、收缩和应力。 六角拉力螺钉 六角拉力螺钉是大型木螺钉,设计为用扳手或套筒而不是螺丝刀驱动。它们具有粗粗螺纹和六角头,可提供出色的扭矩,是最坚固的金属和木材紧固件之一。由于这些螺钉的尺寸和强度,需要预先钻好导向孔。由于其处理重负载的能力,它们非常适合框架、甲板和重型家具等结构应用。 类型 2:螺栓 螺栓与螺钉具有相似的结构,具有从尖端开始的外外螺纹。与螺钉不同,螺栓不是自攻螺纹,也不会在材料中切出螺纹。相反,它们与预攻丝孔或螺母配合使用,以形成坚固的机械接头。以下是最流行的螺栓类型: 六角头螺栓 六角头螺栓有六角头;这种设计使它们可以使用标准扳手或电动工具轻松拧紧或松开,从而确保高效的组装和拆卸。它们带有机器螺纹,可以完全或部分沿螺栓长度延伸。全螺纹螺栓在需要强夹紧力的应用中表现出色,而部分螺纹螺栓凭借其光滑的杆部,可为横向承载应用提供卓越的剪切强度。 马车螺栓 马车螺栓有一个圆形凸形金属头,后面是方颈和螺纹轴。方颈设计用于锁定在材料内,防止螺栓在安装过程中旋转并确保稳定性。这些螺栓主要用于木材应用,例如木框架或家具组装。 吊环螺栓 吊环螺栓一端具有圆形环(或“吊环”),另一端具有螺纹杆。螺纹端拧入表面,而环可以轻松连接或悬挂物体。这些螺栓通常用于需要拉力的应用,例如提升重物或将绳索和电缆固定到结构上。 内六角螺栓(内六角螺栓) 这些类型的紧固件通常具有圆柱形头部,该头部带有用于驱动工具的六角形凹槽。可以使用内六角扳手或六角扳手来拧紧。与传统螺栓(例如带有外驱动头的六角螺栓)相比,内六角螺栓具有更小、更紧凑的头部。这种设计允许在狭小或有限的空间中应用高扭矩。 U 型螺栓 U型螺栓的形状像“U”形,杆部两端都有螺纹。它们可以缠绕管道或其他圆柱形物体,将它们固定在平坦的表面或结构上,而不会对管道造成永久性损坏或影响流体流动。 双头螺栓 双头螺栓,或双头螺栓,两端都有螺纹,中间有一个无螺纹的杆部。它们用于从两侧固定两个或多个零件,通常用于需要双端紧固的法兰组件或结构连接等应用。这些螺栓可以在其一端或两端使用螺母。 类型 3:坚果 螺母是螺栓不可或缺的伙伴。这些紧固件具有内螺纹,与螺纹尺寸和螺距相匹配的螺栓配对,以确保牢固的夹紧和增加的扭矩。与螺栓和螺钉一样,螺母也有各种形状和尺寸。以下是一些最常见的坚果类型: 六角螺母 作为标准六面螺母,六角螺母是最常见的类型,适用于通用紧固。它们很便宜,您可以使用扳手或钳子轻松组装它们。 尼龙锁紧螺母 尼龙锁紧螺母与后继结构的六角螺母类似,但具有一个额外的轴环,可容纳尼龙环或金属嵌件。这种设计有效防止高振动环境下的松动。 城堡螺母(开槽螺母) 城堡螺母的顶部切有槽,类似于城堡的城垛。这些槽与螺栓或螺柱上的预钻孔对齐,螺母就位后,可以将开口销插入孔中以将其固定,防止松动。 法兰螺母 法兰螺母与六角螺母类似,但底部有一个宽法兰,可用作内置垫圈。这种设计有助于将负载均匀分布在更大的区域,降低连接材料损坏的风险并增强螺母的抓力。 盖形螺母(盖形螺母) […]

3D 打印将数字模型转变为真实的物理对象,该过程通常从 STL 文件开始。在本指南中,您将了解什么是 STL 文件、如何创建自己的文件或在线查找现成的文件、如何使用 Cura 或 PrusaSlicer 等切片软件为打印做好准备,以及帮助您获得成功结果的实用技巧。 什么是 STL 文件? STL 代表标准曲面细分语言(有时称为标准三角语言)。它首先用于早期的立体光刻软件,但如今它已成为几乎所有 3D 打印机的标准格式。 STL 文件是 3D 打印机和切片程序可以读取的数字文件格式。它仅定义对象的外部形状,而不存储任何额外的信息,如颜色、纹理或材质。 为此,STL 文件将 3D 模型的表面分解为微小的相连三角形,有点像用小瓷砖覆盖物体。三角形越多,文件的分辨率就越高,这使得曲面看起来更平滑、更真实。较少的三角形使文件更小且处理速度更快,但曲线可能看起来是多面的或“块状的”。在打印之前,您的 STL 将被转换为 G 代码 - 打印机实际遵循的分步说明。 为什么使用 STL 进行 3D 打印? 几乎所有打印机和切片程序都可以读取 STL 文件,无需任何额外的步骤。该格式基于三角形的几何形状使切片软件可以轻松地将 3D 模型转换为可打印图层。同时,STL 文件得到广泛支持:尽管大多数 CAD 程序使用自己的本机格式,但它们几乎总是可以导出为 STL,这使其成为设计工具和打印机之间的通用语言。另一个实际好处是大小 - 因为 STL 仅存储表面几何形状并忽略颜色或纹理等细节,因此文件通常紧凑且易于共享。 (您可能还会遇到其他格式,例如 OBJ,它可以携带颜色和纹理等额外数据。要了解两者的比较,请查看 STL 与 OBJ。) STL […]

在为特定应用选择坚固的金属材料时,钛和钢通常被认为是首选。除了强度差异之外,每种金属还具有独特的性能,使其适用于各种用途。哪一种是您项目的正确选择?本文将概述这两种金属并比较它们的主要特性。让我们开始吧。

عربي

عربي

中国大陆

简体中文

United Kingdom

English

France

Français

Deutschland

Deutsch

नहीं

नहीं

日本

日本語

Português

Português

España

Español