Specify the exact surface treatment method such as anodizing, electroplating, or powder coating.

If unsure about the best treatment option, consult with our experts to determine the most cost-effective and suitable solution based on material properties and your usage requirements.

English

Capabilities

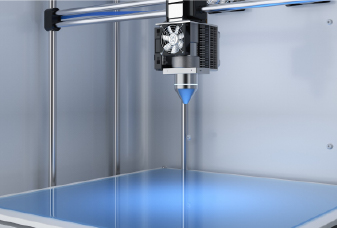

Rapid prototyping and on-demand manufacturing.

Industries

Join thousands of industry leaders driving product innovation with Chiggo.

Medical Devices

Aerospace

Consumer Products

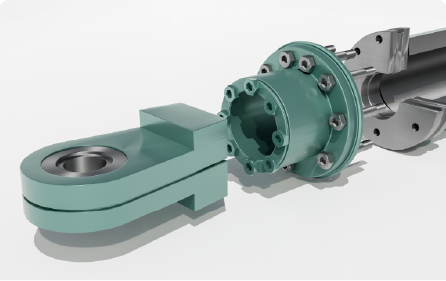

Industrial Equipment

Delivering innovations swiftly and safely to healthcare

Propelling projects from blueprint to takeoff with efficiency

Shaping products that define modern living, from idea to use

Powering progress with advanced machinery for superior productivity

Solutions

A one-stop solution from raw materials to production and product enhancement.

About Us

Discover who we are and how we ensure quality and timely delivery.

About Chiggo

About Delivery

Quality Assurance

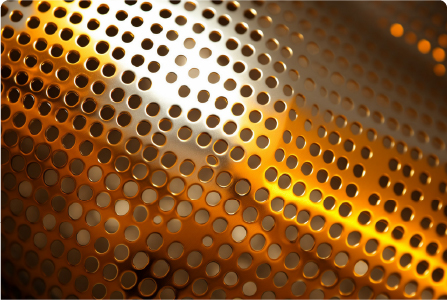

Our Factory

Our vision, mission, development history, and dedicated team.

Rapid and efficient turnaround times, optimizing every step from order placement to delivery.

Delivering quality rapid prototyping and on-demand production parts that meet and exceed expectations.

Discover the precision and innovation behind Chiggo with a tour of our factory, available online or on-site.

Resource

Everything you need to know about digital manufacturing.

-

Blog

-

Video

Your Trusted Source FactorySince 2011