English

行业

加入成千上万的行业领导者的行列,与 Chiggo 一起推动产品创新。

解决方案

从原材料到生产和产品增强的一站式解决方案。

资源

您需要了解的有关数字化制造的一切。

3D打印和CNC加工是最受欢迎的两个制造过程今天。两种方法都依赖数字控制系统来快速生产原型,并适合创建准确的定制最终用途零件。

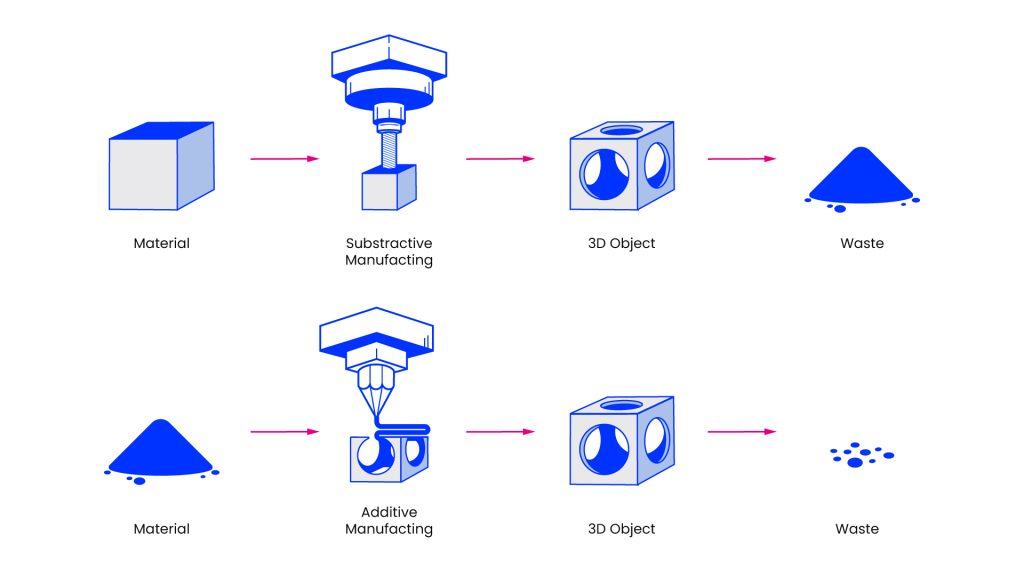

但是,它们几乎在各个方面都有不同 - 在生产坚固的零件方面,它们甚至是直接的竞争对手。最大的区别是一种方法逐层构建零件,而另一个方法是通过删除材料来构建零件的。如果您发现自己在CNC加工和产品的3D打印之间进行选择,请继续阅读以了解更多信息。

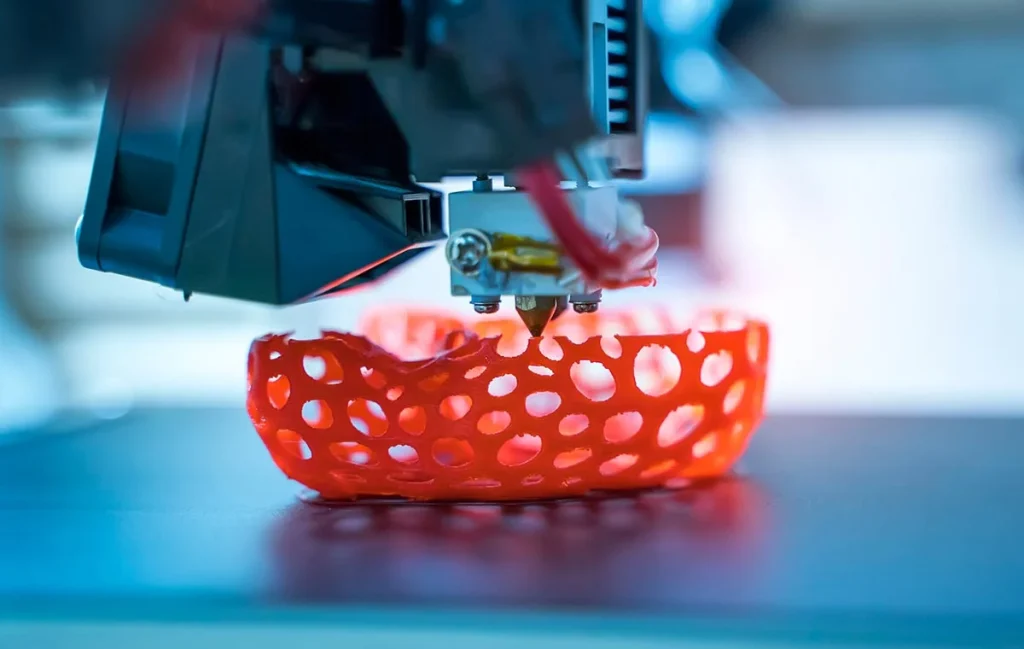

3D打印,也称为增材制造,是一个过程,它通过逐层添加材料来从数字模型中创建三维对象。该过程始于数字模型,该模型可以使用从3D扫描仪获得的CAD(计算机辅助设计)软件创建,也可以从在线存储库中下载。接下来,将模型导入切片软件,该软件将其分为许多二维横截面层,这些层用作打印机的蓝图。然后,切片软件将这些层转换为一系列指令(通常是G代码),即3D打印机可以理解。此外,如果该模型包含悬垂零件,则该软件可能会生成支持结构以确保正确打印。最后,打印机遵循这些说明,通过一层沉积材料,并将每个新层粘合到其下面的一个,并逐渐构建完整的对象。

1980年代后期,查克·赫尔(Chuck Hull)发明了立体光刻(SLA),这是第一个3D打印技术。随着新材料和技术进步的持续研究,出现了更多的3D打印技术。今天的常见类型包括:

尽管3D打印是一个尖端的添加剂制造过程,但CNC加工(计算机数值控制加工)代表了一种更传统的减法制造技术。 CNC加工在1950年代从1950年代出现,随着数字自动化的发展,CNC加工已经发展起来,从而使整个行业都可以高精度制造。

要获取CNC部分,您首先使用CAD软件创建数字模型。然后,通过CAM编程将该模型转换为机器可读的G代码,该编程指定了精确的运动,速度和操作。之后,工件牢固地安装在CNC机器上,并选择和安装适当的切割工具。 CNC机器遵循G代码:从粗加工开始,以去除多余的材料,然后继续进行精细加工以实现最终的尺寸和表面光洁度。

在制造业中广泛使用的CNC加工有几种常见类型:

两种技术都具有独特的优势 - CNC加工具有高精度和材料的多功能性,而3D打印是创建复杂的几何形状和快速原型制作的优选。它们之间的选择取决于各种因素,包括材料需求,设计复杂性,生产速度和预算考虑。

下面的快速检查表提供了简短的比较,可帮助您确定哪种过程最适合您的需求,或者两者的组合是否可能产生最佳结果。

| 因素 | 3D打印 | CNC加工 |

| 材料选择 | ▪ Limited but expending options ▪ Flexible materials and superalloy | ▪ Wide range , including metals, plastics, wood, and composites |

| 设计复杂性 | ▪ Can achieve highly complex geometries, including lattice structures and organic shapes | ▪ Can produce parts with relatively complex features, such as threaded holes, sharp edges, and curves ▪ Limited by tool accessibility, tool path and type, axis-defined minimum radii, and the need for repositioning during the process |

| 精确 | ▪ Moderate precision, typically ±0.1 mm, though high-end printers can achieve tighter tolerances | ▪ High precision, often ±0.005 mm or better, depending on material and machine ▪ Excellent repeatability |

| 表面饰面 | ▪ Requires post-processing (e.g. sanding, painting) for a smooth finish ▪ Some 3D printing processes produce surfaces that are grained, rough, and stepped, or features that may appear blurred | ▪ Smooth finish with little to no post-processing (typical 125 Ra finish as machined) |

| 大零件尺寸 | ▪ Up to 914 x 610 x 914 mm (e.g. FDM) ▪ Ideal for smaller prototypes or assemblies | ▪ Up to 2000 x 800 x1000 mm ▪ Suitable for industrial housings and large-scale prototypes |

| 力量 | ▪ In FDM, layer adhesion and print orientation reduce the strength of parts ▪ Metal 3D printed parts in SLM and DMLS offer strength comparable to or even better than traditionally machined parts, especially when heat-treated or made with specific alloys | ▪ The internal structure of parts is continuous, and their strength usually remains at 100% of the native material ▪ Some high-strength alloys may be impossible or difficult to process with extreme precision |

| 设置 | ▪ Minimal setup, require only a digital file and slicer software | ▪ Need workpiece fixation, tool selection, and machine calibration ▪ G-code programming,toolpath generation, and potential part repositioning |

| 构建速度 | ▪ Low setup time, but build time can take hours ▪ Quicker for small batches and complex designs ▪ Ideal for design validation, rapid prototyping, and test fits | ▪ Can take ages to set up and program, but cutting can be very fast ▪ Fast for bulk production |

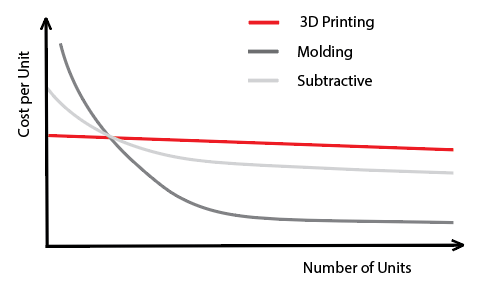

| 成本 | ▪ Cost-effective for small series or custom one-offs ▪ Slight variations in your product’s size can significantly increase your 3D printing manufacturing costs | ▪ More economical for high-volume production ▪ More material waste |

接下来,我们可以通过询问以下一系列问题来确定您是否应该选择CNC加工,3D打印或两者为您的项目。

3D打印和CNC对金属和塑料进行加工。 CNC加工具有更广泛的材料适应性。尽管塑料变得越来越受欢迎,但它主要用于从金属生产零件。您也可以使用CNC工艺来制造木材,复合材料,甚至泡沫和蜡的零件。

最常见的CNC材料:

3D打印主要与热塑性,树脂和一些金属粉末一起使用。但是,3D打印的金属零件并不便宜,尽管情况正在发生变化。

常见的3D打印材料:

值得注意的是,非常柔软,柔性的材料(例如TPU和硅酮)在切割力下倾向于变形,从而使精确的加工变得困难。同样,某些超级合金由于高强度,工作硬化和耐热性而对机器的挑战。对于这些材料,3D打印可能是一个更好的选择。

尽管5轴或更高级的机器可以处理非常复杂的几何形状,但由于工具无法访问该部件的所有表面,因此仍然很难(甚至不可能)创建隐藏的功能和底切。切割工具本身的几何形状也限制了加工完美正方角的能力。此外,通常需要定制固定装置或夹具,这可能是一个重要的限制。

3D打印机消除了CNC加工中的这些几何挑战。它们可以相对轻松地产生高度复杂的几何形状。尽管SLM等过程可能需要支持结构,但额外的后处理并没有降低3D打印提供的巨大设计自由和复杂性。

由于材料收缩和打印过程的分辨率限制,因此3D打印通常不如CNC加工精确。例如,在标准条件下,诸如SLA之类的精确3D打印技术通常达到±0.1mm的公差。相比之下,精确的CNC机器可以容纳高达±0.025mm(0.001英寸)甚至更好的公差。

当涉及重复性3D打印时,即使是SLA或DLP等高精度方法,仍然落后于CNC加工。 CNC机器由于其刚性机械设置,精确的控制系统以及减法过程的均匀性提供了较高的一致性。相反,3D打印更容易受到材料收缩,层粘附和环境因素引起的变异性。

像SLA这样的3D打印机可以生产具有细,光滑和纹理层的零件,但是使用正确的工具的CNC加工可以实现甚至更光滑的表面。

可以通过各种表面完成选项提高零件的功能和外观品质。例如,CNC加工的零件可以阳极氧化,粉末 - 粉末,粉状,珠子涂成珠和言行。同样,3D打印零件的表面整理选项包括 plating ,,珠子爆破,抛光,抛光,抛光和热处理以增强产品。

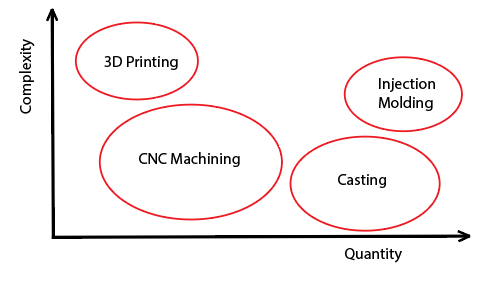

对于具有典型几何形状的部分(可以通过CNC相对容易实现的部分),选择取决于零件的材料和数量。

塑料零件:

对于金属零件,情况大不相同:

为您的自定义零件选择正确的制造技术似乎是一个无法克服的挑战,但这并不是一定。正如我们总是在Chiggo告诉客户,没有完美的,适合所有的制造方法。最佳选择取决于各种因素。为了帮助指导您的决定,我们汇总了一些基本的经验法则:

如果您仍然不确定自己的最佳制造方法,请与我们的工程师联系并上传您的设计。 Chiggo是 CNC加工和中国的3D打印服务的领先提供商,并在这里有一支经验丰富的团队为您提供帮助!

想一想金属汤匙。如果您在手柄上轻轻按下,它会弯曲一点,但放手后立即弹回。不过,更努力地推动,勺子会永久弯曲。那时,您已经超越了汤匙的屈服强度。在本文中,我们将探讨屈服强度的含义,与相关思想(如拉伸强度和弹性限制)进行比较,以及为什么在现实世界中它很重要。我们还将研究影响强度和常见材料的典型值的因素。 什么是屈服强度? 屈服强度是材料开始永久变形的应力水平。简而言之,这是材料停止反弹(弹性行为)并以无法完全逆转的方式弯曲或伸展的点。在屈服强度以下,当您卸下力时,材料恢复为原始形状(就像弹簧可以追溯到其长度)。超过屈服强度,材料永远改变了:它已经屈服了,这意味着它已经经历了塑性变形。 为了更好地理解这一点,让我们分解两个关键术语:压力和压力。应力是将力施加到材料除以其横截面区域的材料,或仅仅是材料内部力的强度。您可以将其视为压力,但压力描述了内部反应而不是外部推动。应变是材料在响应中的变化多少,计算为长度的变化除以原始长度。当我们策划压力抵抗压力时,我们会得到一个应力 - 应变曲线这显示了材料随着负载的增加的表现。 在应力 - 应变曲线的早期,材料的行为表现:压力和应变是成比例的(根据Hooke定律的直线),一旦去除负载,材料就会恢复其原始形状。该区域的末端是弹性限制 - 占地,某些变形仍然是永久性的。屈服强度标志着从弹性行为到塑性行为的转变,并定义了可逆变形和不可逆变形之间的边界。 对于许多延性金属,例如低碳钢,这种过渡是逐渐而不是锋利的。为了始终定义屈服强度,工程师经常使用0.2%的偏移方法:他们绘制一条平行于曲线弹性部分的线,但变为0.2%应变。该线相交曲线的点被视为屈服强度。这提供了一种实用,标准化的方法,即使不存在明显的产量点,也可以测量屈服强度。 屈服强度与拉伸强度 正如我们所定义的那样,屈服强度是材料开始永久变形的压力。拉伸强度(通常称为终极拉伸强度(UTS))是材料破裂之前可以承受的最大压力。一旦达到该点,材料将不再承担额外的负载,并且很快就会裂缝。 两者都描述了材料对压力的反应,但它们代表不同的限制:屈服强度标志着永久变形的开始,而拉伸强度则标志着断裂点。例如,在拉动钢棒时,它首先会弹性伸展。超越屈服强度,并实现永久伸长率。继续前进,直到达到拉伸强度为止,杆最终将抢购。 在实践设计中,工程师更多地专注于产量强度,因为组件必须保持功能,而不会造成持久损坏。拉伸强度仍然很重要,但通常标志着失败条件永远不会在服务中发生。 除拉伸强度外,屈服强度还经常与其他两个概念相混淆: 弹性极限:弹性极限是材料可以承受的最大应力,一旦去除负载,仍将完全返回其原始形状。低于此极限,所有变形都是弹性和可逆的。在许多情况下,弹性极限非常接近屈服强度,因此两者通常被视为相同。尽管弹性极限标志着精确的物理边界,但屈服强度提供了标准化的工程值,可以始终如一地测量并用于安全设计。 比例极限:该术语来自应力 - 应变曲线的线性部分。比例限制是遵循胡克定律的压力和压力直接比例增加的点。它通常发生在弹性极限和屈服强度之前。在这一点之外,曲线开始弯曲 - 尽管材料仍然具有弹性,但这种关系不再是完美的线性。 影响力强度的因素 屈服强度无法保持固定 - 它可以根据几种物质和环境因素而改变。这是一些最常见的: 材料组成(合金元素) 金属的构成对其产量强度产生了重大影响。在金属中,添加合金元素可以使它们变得更坚固。例如,当添加碳,锰或铬等元素时,钢的强度也会增强 - 尽管碳也更脆。铝合金从铜,镁或锌等元素中获得强度。这些添加物在金属内部产生了微小的障碍,从而阻止了位错运动(塑性变形的原子级载体),从而提高了强度。简而言之,金属的“食谱”可以使弯曲更难或更容易。这就是为什么苏打中的铝易于柔软而柔软的,而飞机机翼中的铝(与其他金属混合在一起)具有更高的屈服强度。 晶粒尺寸(微观结构) 通常,较小的晶粒意味着更高的强度,这是霍尔 - 格什关系描述的趋势。原因是晶界充当脱位运动的障碍,因此更细的谷物会产生更多的障碍,并使金属更强壮 - 到达一点点。冶金学家通过控制的固化或热机械处理来完善晶粒尺寸。例如,许多高强度的钢和超合金用非常细的晶粒设计以最大化屈服强度,而晶粒非常大的金属往往更容易产生。 热处理 金属加热和冷却的方式可以改变其结构,从而改变其屈服强度。退火(缓慢加热和冷却)软金属,降低其屈服强度,并通过缓解内部应力来使其更具延展性。淬火(在水或油中快速冷却)将结构锁定到坚硬的,压力的状态,大大提高了屈服强度,但也使金属变脆。为了恢复平衡,淬灭通常是回火,一个适度的加热步骤,可改善韧性。 通过选择正确的热处理,制造商可以根据应用使金属更难或更柔软。例如,对弹簧钢进行处理以达到高屈服强度,因此它可以弯曲而不会变形,而钢丝首先要退火以易于塑形,然后再加强。 制造过程(冷工作) 如何机械处理材料也可以改变其屈服强度。冷工作(在室温下变形金属,例如冷滚动或冷图)通过称为工作硬化的机制提高了强度。当您将金属变形时,您会在其晶体结构中引入错位和纠缠,这使得进一步变形更加困难 - 实际上,金属随着变形而变得更强壮。这就是为什么在热卷(不工作)条件下,冷滚动钢通常比同一钢具有更高的屈服强度。 温度和环境 根据经验,大多数金属在高温下会失去屈服强度。热使金属变软,因此可以用较小的力变形。在非常低的温度下,有些材料变得更加脆弱。它们塑性变形的能力降低了,因此尽管屈服应力在技术意义上可能会增加,但它们比产量更有可能破裂。 诸如腐蚀或辐射等环境因素也会降解材料。腐蚀会产生凹坑或减少横截面区域,从而有效减少结构在屈服之前可以承受的负载。例如,生锈的钢梁在载荷下可能会产生的厚度比未腐蚀的束较低,因为其有效厚度会降低,并且来自锈蚀的微裂缝会浓缩压力。 产量不同材料的强度 应力 - 应变曲线提供了一种简单的方法来比较不同材料对负载的反应方式。在上图中,我们可以看到四个典型的行为。随着压力的增加,每个反应都不同,其屈服强度反映了这些差异。 脆性材料:脆性材料,例如玻璃或陶瓷,几乎没有塑性变形。他们沿着几乎直线直线直至突然断裂。他们的屈服强度非常接近他们的最终力量,因为他们并没有真正“屈服” - 它们中断。 强但不是延性材料:某些材料(例如高强度钢)可以承受高应力,但显示有限的延展性。它们具有很高的屈服强度,这意味着它们可以很好地抵抗永久性变形,但是在破裂之前并没有伸展太多。 […]

数控车削是应用最广泛的数控加工工艺之一,因其精度和多功能性而在制造业中备受推崇。它涉及一种固定切削刀具,用于从车床或车削中心上的旋转工件上去除材料。该工艺主要用于生产具有圆形或轴对称特征的零件。根据切割操作的类型,它可以创建圆柱形、圆锥形、螺纹、凹槽或孔部件,以及具有特定表面纹理的零件。

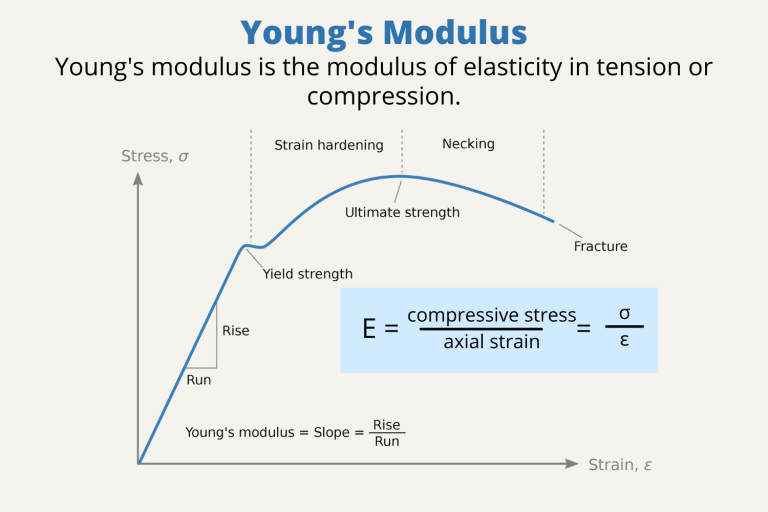

从摩天大楼到喷射机翼,每个工程结构都依靠材料刚度安全,有效地性能。 Young的模量(弹性区域的应力与应变之比)是该刚度的普遍度量。通过了解Young的模量,设计师可以准确预测多少梁将弯曲或在负载下弹跳,从而在不建造过度的情况下确保安全性。这篇文章呈现了Young的模量 - 它是什么,如何计算,比较通用材料,工业应用等E值的比较。

عربي

عربي

中国大陆

简体中文

United Kingdom

English

France

Français

Deutschland

Deutsch

नहीं

नहीं

日本

日本語

Português

Português

España

Español