English

Capacidades

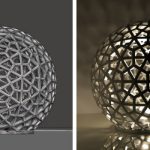

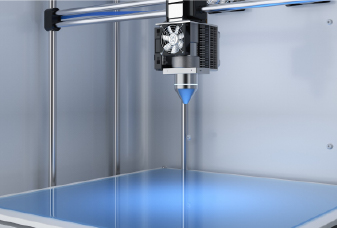

Prototipagem rápida e fabricação sob demanda.

Indústrias

Junte-se a milhares de líderes do setor que impulsionam a inovação de produtos com a Chiggo.

Dispositivos Médicos

Aeroespacial

Produtos de consumo

Equipamentos Industriais

Fornecendo inovações com rapidez e segurança para a área da saúde

Impulsionando projetos desde o projeto até a decolagem com eficiência

Moldar produtos que definem a vida moderna, da ideia à utilização

Impulsionando o progresso com maquinário avançado para produtividade superior

Soluções

Uma solução completa, desde matérias-primas até produção e aprimoramento de produtos.

Sobre nós

Descubra quem somos e como garantimos qualidade e entrega pontual.

Sobre Chigo

Sobre a entrega

Garantia de qualidade

Nossa fábrica

Nossa visão, missão, histórico de desenvolvimento e equipe dedicada.

Tempos de resposta rápidos e eficientes, otimizando cada etapa, desde a colocação do pedido até a entrega.

Fornecendo prototipagem rápida de qualidade e peças de produção sob demanda que atendem e superam as expectativas.

Descubra a precisão e a inovação por trás da Chiggo com um tour pela nossa fábrica, disponível online ou no local.

Recurso

Tudo o que você precisa saber sobre fabricação digital.

-

Blogue

-

Vídeo

Sua fábrica de fontes confiáveisDesde 2011

-NC加工-448X301.jpg?width=448&height=301)