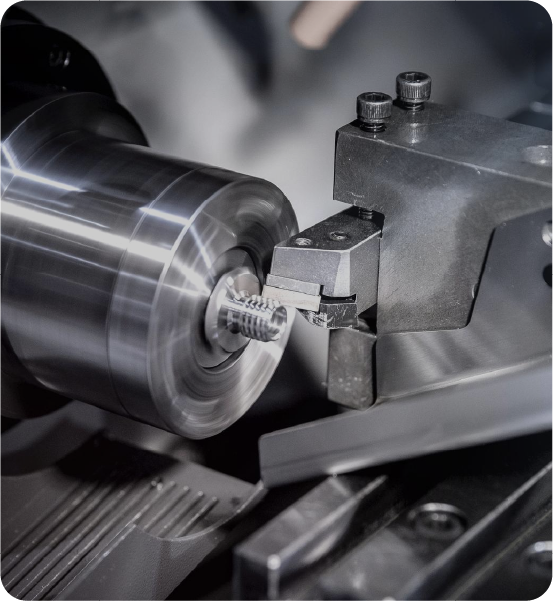

गुणवत्ता मानकीकृत उत्पादन से शुरू होती है। जब तक अन्यथा निर्दिष्ट न किया जाए, हम ISO-2768 विनिर्माण मानकों का पालन करते हैं। उन्नत उपकरण, पेशेवर इंजीनियरों और कुशल ऑपरेटरों की हमारी टीम के साथ मिलकर, हमें सख्त सहनशीलता हासिल करने और लागत को अनुकूलित करते हुए शीर्ष पायदान परिणाम देने की अनुमति देते हैं।

English

क्षमताओं

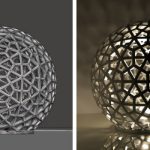

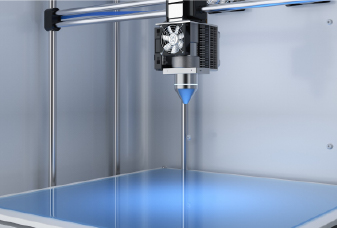

तीव्र प्रोटोटाइपिंग और ऑन-डिमांड विनिर्माण।

इंडस्ट्रीज

चिग्गो के साथ उत्पाद नवाचार को बढ़ावा देने वाले हजारों उद्योग जगत के नेताओं से जुड़ें।

चिकित्सा उपकरण

एयरोस्पेस

उपभोक्ता उत्पाद

औद्योगिक उपकरण

स्वास्थ्य देखभाल के लिए नवाचारों को तेजी से और सुरक्षित रूप से वितरित करना

दक्षता के साथ परियोजनाओं को ब्लूप्रिंट से टेकऑफ़ तक ले जाना

ऐसे आकार देने वाले उत्पाद जो विचार से लेकर उपयोग तक आधुनिक जीवन शैली को परिभाषित करते हैं

बेहतर उत्पादकता के लिए उन्नत मशीनरी के साथ प्रगति को सशक्त बनाना

समाधान

कच्चे माल से लेकर उत्पादन और उत्पाद संवर्धन तक वन-स्टॉप समाधान।

हमारे बारे में

जानें कि हम कौन हैं और हम गुणवत्ता और समय पर डिलीवरी कैसे सुनिश्चित करते हैं।

चिग्गो के बारे में

डिलिवरी के बारे में

गुणवत्ता आश्वासन

हमारी फ़ैक्टरी

हमारा दृष्टिकोण, मिशन, विकास इतिहास और समर्पित टीम।

त्वरित और कुशल टर्नअराउंड समय, ऑर्डर प्लेसमेंट से लेकर डिलीवरी तक हर चरण को अनुकूलित करना।

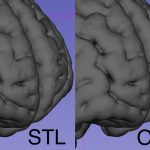

गुणवत्ता वाले रैपिड प्रोटोटाइप और ऑन-डिमांड उत्पादन भागों को वितरित करना जो अपेक्षाओं को पूरा करते हैं और उससे अधिक हैं।

ऑनलाइन या साइट पर उपलब्ध हमारे कारखाने के दौरे के साथ चिग्गो के पीछे की सटीकता और नवीनता की खोज करें।

संसाधन

डिजिटल विनिर्माण के बारे में वह सब कुछ जो आपको जानना आवश्यक है।

-

ब्लॉग

-

वीडियो

आपकी विश्वसनीय स्रोत फ़ैक्टरी2011 के बाद से