English

Fähigkeiten

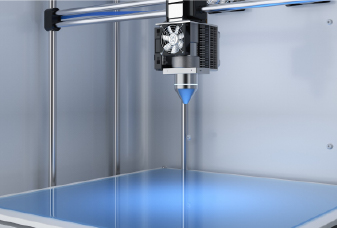

Rapid Prototyping und On-Demand-Fertigung.

Branchen

Schließen Sie sich Tausenden von Branchenführern an, die mit Chiggo Produktinnovationen vorantreiben.

Medizinische Geräte

Luft- und Raumfahrt

Konsumgüter

Industrieausrüstung

Innovationen schnell und sicher im Gesundheitswesen bereitstellen

Projekte mit Effizienz vom Entwurf bis zum Start vorantreiben

Wir gestalten Produkte, die modernes Wohnen definieren, von der Idee bis zur Nutzung

Fördern Sie den Fortschritt mit fortschrittlichen Maschinen für überlegene Produktivität

Lösungen

Eine Komplettlösung vom Rohstoff bis zur Produktion und Produktveredelung.

Über uns

Entdecken Sie, wer wir sind und wie wir Qualität und pünktliche Lieferung sicherstellen.

Über Chiggo

Informationen zur Lieferung

Qualitätssicherung

Unsere Fabrik

Unsere Vision, Mission, Entwicklungsgeschichte und unser engagiertes Team.

Schnelle und effiziente Bearbeitungszeiten, die jeden Schritt von der Auftragserteilung bis zur Lieferung optimieren.

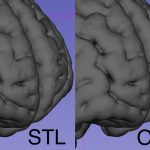

Bereitstellung hochwertiger Rapid-Prototyping- und On-Demand-Produktionsteile, die die Erwartungen erfüllen und übertreffen.

Entdecken Sie die Präzision und Innovation hinter Chiggo bei einem Rundgang durch unsere Fabrik, der online oder vor Ort verfügbar ist.

Ressource

Alles, was Sie über die digitale Fertigung wissen müssen.

-

Blog

-

Video

Ihre vertrauenswürdige QuellenfabrikSeit 2011