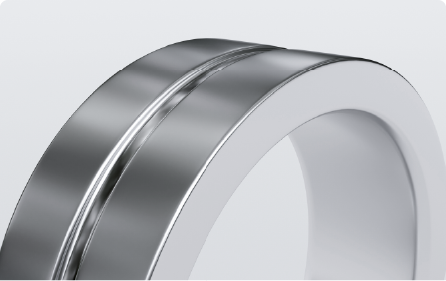

قد يؤدي تشطيب السطح إلى حدوث عيوب جمالية مثل علامات التعليق الناتجة عن الأكسدة. تحديد أنواع العيوب المقبولة بوضوح وتحديد حدود هذه العيوب.

الجانب A (السطح الأساسي) نحن نضمن إنتاجًا خاليًا من العيوب للجانب A، وهو السطح الأكثر أهمية من الناحية الجمالية، وعادة ما يكون الجانب المرئي من منزلك المنتج.

الجانب B (السطح الثانوي)الجانب B، الذي عادةً ما يكون مخفيًا عن الأنظار بعد التجميع، قد يشتمل على عيوب بسيطة مثل علامات التعليق. ومع ذلك، سيكون خاليًا من الخدوش والبقع والعيوب.

حدد العدد المسموح به أو نسبة العيوب. في Chiggo سيتم فحص جميع الدفعات وفقًا لمعايير AQL من المستوى الثاني